The Benefits of Automated Fabric Tensile Testers in Textile Testing Laboratories

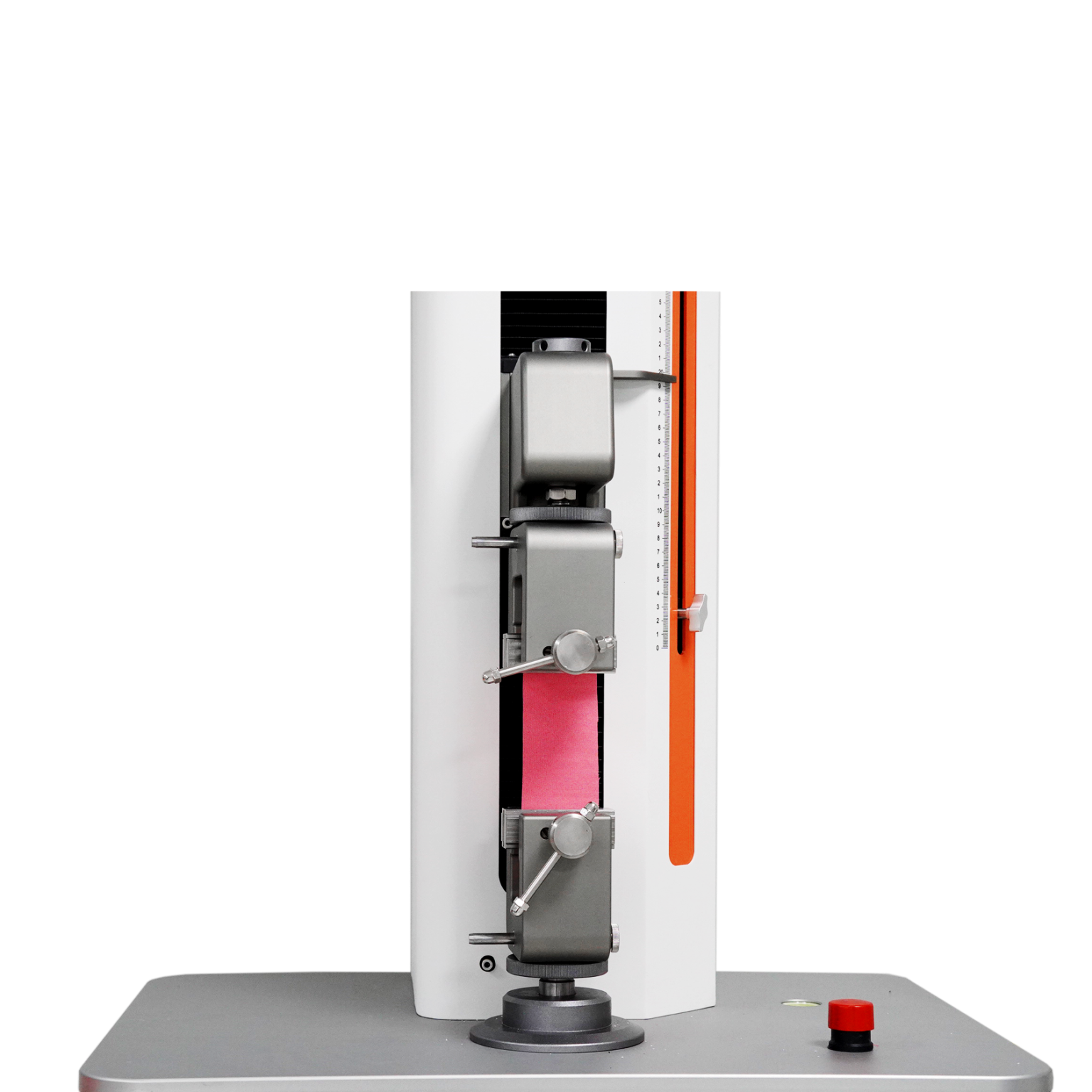

In the ever-evolving textile industry, ensuring the durability and reliability of fabrics is crucial for both manufacturers and consumers. A fabric’s strength is one of the primary factors determining its performance and quality, whether it’s for apparel, industrial applications, or home textiles. To assess this strength, textile testing laboratories rely heavily on fabric tensile strength testers. With advancements in technology, the introduction of automated tensile testing systems has revolutionized the testing process, offering a multitude of benefits for textile laboratories.

Increased Accuracy and Consistency

Traditional manual tensile testing methods can be prone to human error, especially when measuring the force required to break the fabric or calculating elongation. Automated tensile test equipment eliminates these inconsistencies by using precise digital systems that can consistently measure and record data without human intervention. This not only increases the accuracy of the results but also ensures that measurements are standardized across multiple tests, providing reliable data for quality control purposes.

Moreover, automated systems are equipped with sensors that detect slight variations in fabric properties, ensuring that even the smallest discrepancies are captured. This level of precision is particularly beneficial for fabrics that are expected to meet strict international standards, as it guarantees that they will perform as expected under various conditions.

Enhanced Productivity

In a busy textile testing laboratory, time efficiency is a key factor. Automated fabric tensile strength tester significantly reduces the time required for each test compared to manual methods. The automated systems can run continuous tests on multiple fabric samples simultaneously, allowing lab technicians to handle more tests in less time. This increase in throughput is particularly valuable for labs that work with large volumes of fabric samples or those serving numerous clients who require fast turnaround times.

Additionally, automation minimizes the need for manual interventions, reducing downtime due to re-calibration or manual data entry errors. This leads to higher operational efficiency, making it possible for laboratories to allocate resources to other critical tasks.

Improved Data Management

Data management is another area where automated tensile testing excels. These systems are often integrated with laboratory management software that automatically logs test results, organizes data, and generates detailed reports. This eliminates the need for paper records, which can be time-consuming and prone to mistakes. Digital records are easy to store, retrieve, and analyze, enabling textile labs to track trends, monitor the performance of fabrics over time, and make data-driven decisions.

Furthermore, automated tensile test equipment allows for real-time data visualization, providing operators with immediate feedback on fabric performance. This instant insight is invaluable for both quality assurance and troubleshooting, as it helps labs identify potential issues before they escalate.

Cost Efficiency

Though the initial investment in automated testing equipment may seem high, the long-term cost benefits are substantial. Automated systems reduce the labor required for testing, which translates to lower operational costs over time. Additionally, they help avoid the costs associated with inaccurate test results, such as faulty batches, returns, and reputation damage due to poor product quality. By ensuring that only high-quality fabrics pass through rigorous tensile strength tests, manufacturers can reduce waste and enhance their bottom line.

Moreover, automated systems require less maintenance compared to manual testing setups, which often involve mechanical components that wear out over time. With fewer breakdowns and less need for repairs, automated fabric tensile strength testers offer a more cost-effective solution in the long run.

Enhanced Safety

Safety is a paramount concern in any laboratory, and automated tensile testing equipment provides a safer working environment. Traditional manual testing may involve handling heavy, force-exerting machines, which can pose risks to lab personnel. Automated systems are designed with safety protocols that prevent operators from being in direct contact with the equipment during operation, reducing the likelihood of accidents or injuries.

Furthermore, the automation of the testing process ensures that fabric samples are subjected to controlled, uniform stress, reducing the chances of unexpected failures that could endanger workers or damage equipment.

Conclusion

The integration of automated fabric tensile strength testers into textile testing laboratories has proven to be a game-changer for the industry. With enhanced accuracy, efficiency, data management, and safety, automated tensile test equipment ensures that fabric testing is not only faster but also more reliable and cost-effective. Textile Testing Machine-TESTEX plays a crucial role in this advancement, offering cutting-edge solutions for precise and efficient testing. For textile manufacturers and testing laboratories striving to meet the ever-increasing demands for quality and innovation, investing in automated tensile testing solutions is an essential step toward maintaining competitiveness in the global market.

For more information on textile testing methods/standards

or Textile Testing Machine-TESTEX textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com sales@tes.hk

Deepak Sharma

Namaste! I’m Deepak Sharma, the creative mind behind SocialFunda, your go-to hub for Facebook bios, captivating captions, Instagram bios, and a treasure trove of Hindi Shayari. As a digital enthusiast, I am passionate about curating content that adds a touch of flair to your online presence.