Innovative Fertilizer Production with NPK Dry Granulation Equipment and Powder Granulator Machine

In the modern agricultural industry, the demand for high-quality fertilizers has never been greater. Farmers are increasingly seeking nutrient-rich and environmentally friendly fertilizers to improve soil health and boost crop yields. To meet this growing need, advanced granulation technologies have revolutionized the fertilizer production process. Among these, NPK dry granulation equipment and the powder granulator machine stand out as essential tools that ensure efficiency, precision, and sustainability in fertilizer manufacturing.

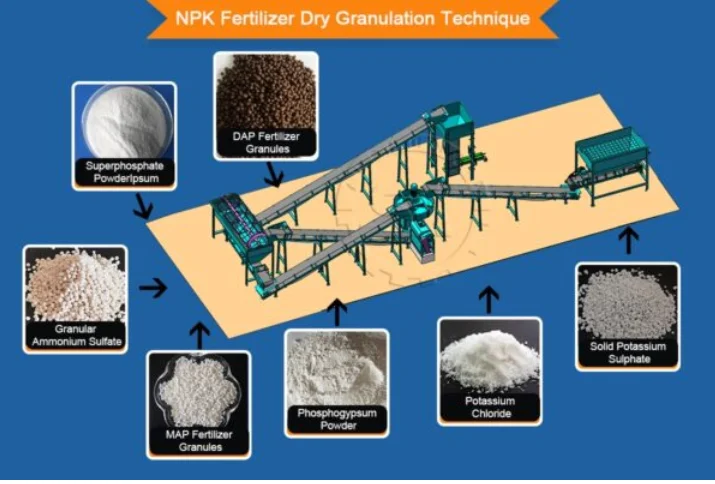

Understanding NPK Dry Granulation Technology

NPK dry granulation equipment is designed for producing compound fertilizers that contain the three primary nutrients required for plant growth — nitrogen (N), phosphorus (P), and potassium (K). The process of dry granulation does not require the addition of water or heat, making it highly energy-efficient and environmentally friendly compared to wet granulation methods.

In this process, the powdered NPK raw materials are compressed into dense sheets using a roller compactor or double-roller press. These sheets are then crushed and screened to form uniform granules that are easy to package, store, and apply. The dry granulation process is ideal for large-scale fertilizer production because it reduces operational costs, minimizes waste, and enhances nutrient retention in each granule.

A prime example of this innovation is the 20 T/H NPK Dry Granulation Line offered by Yushunxin Machinery. This line can produce up to 20 tons of compound fertilizer per hour, making it a perfect choice for industrial-scale operations. The equipment features a compact design, high granulation rate, and minimal dust emission, ensuring both productivity and environmental protection.

Key Components of NPK Dry Granulation Equipment

A typical NPK dry granulation equipment line consists of several major components that work together to transform raw materials into premium fertilizer granules:

- Feeding System:

The raw materials — such as urea, ammonium sulfate, monoammonium phosphate, and potassium chloride — are accurately fed into the system using metering and mixing devices.

- Double Roller Press Granulator:

This is the heart of the dry granulation line. It compresses the powder into dense sheets under high pressure without using any liquid binder. The rollers can be customized with different surface designs to produce specific granule shapes and sizes.

- Crushing and Screening System:

After compaction, the material sheets are broken into smaller granules. The screening system separates qualified granules from fine powders, which are then recycled back into the process for maximum efficiency.

- Packaging Unit:

The final product — uniform, strong, and dust-free granules — is automatically weighed and packed for transport or sale.

The result is a clean, efficient production line capable of delivering consistent, high-quality fertilizer granules that are easy to distribute and apply in the field.

Advantages of Using NPK Dry Granulation Equipment

The adoption of NPK dry granulation equipment offers numerous benefits for fertilizer manufacturers and end-users alike:

- Energy Efficiency: The dry granulation process eliminates the need for drying and cooling steps, saving both energy and time.

- Environmental Protection: With no water or steam involved, there is minimal risk of wastewater or exhaust gas emissions.

- Cost Reduction: The equipment operates with fewer auxiliary systems, reducing operational and maintenance expenses.

- High Granule Strength: The double roller press creates dense, durable granules that resist crushing during storage and transportation.

- Nutrient Preservation: The process prevents nutrient loss from heat or moisture exposure, ensuring the final fertilizer maintains optimal nutrient value.

In large fertilizer plants, this technology not only increases production capacity but also helps meet modern environmental and safety standards.

The Role of the Powder Granulator Machine

While the NPK dry granulation system is ideal for compound fertilizers, the powder granulator machine serves a broader range of industrial applications. This equipment is used to granulate fine powder materials such as limestone, dolomite, gypsum, and other non-metallic minerals into uniform granules.

For example, the Limestone Powder Granulator Machine from Yushunxin Machinery can process 1–3 tons of powder per hour, producing granules with a size range of 3–10 mm. This machine is widely used not only in the fertilizer industry but also in feed production, building materials, and environmental applications like flue gas desulfurization.

How the Powder Granulator Machine Works

The powder granulator machine uses a similar dry compaction principle as the NPK granulator. Fine powders are fed between two high-pressure rollers that compress them into solid sheets. The sheets are then crushed, screened, and classified into granules of the desired size.

The process does not require any liquid binder or heat, which makes it suitable for moisture-sensitive materials. Moreover, since no drying or cooling is needed, the machine provides a simple, cost-effective solution for turning powders into high-value products.

Benefits of the Powder Granulator Machine

- Wide Application Range:

Suitable for mineral powders, fertilizers, chemical additives, and industrial waste recycling.

- Energy Saving:

Operates with low energy consumption due to the absence of drying and cooling stages.

- Compact Design:

Requires minimal space and can be integrated easily into existing production lines.

- Product Quality:

Produces granules with uniform size, high strength, and excellent flowability for easier storage and transportation.

- Eco-Friendly Operation:

Generates minimal dust and no wastewater, making it an environmentally responsible choice.

By using the powder granulator machine, manufacturers can convert low-value powders into marketable granules, reducing waste and increasing profitability.

Comparing the Two Granulation Solutions

Both the NPK dry granulation equipment and the powder granulator machine rely on dry compaction technology, but they cater to different scales and materials:

| Feature | NPK Dry Granulation Equipment | Powder Granulator Machine |

| Main Application | NPK Compound Fertilizer Production | Mineral Powders (Limestone, Dolomite, etc.) |

| Capacity | Up to 20 tons/hour | 1–3 tons/hour |

| Process Type | Complete Production Line | Single Granulation Unit |

| Energy Use | Low (No drying required) | Very Low |

| Granule Size | 2–6 mm | 3–10 mm |

| Investment | Medium to High | Low to Medium |

| Best For | Large fertilizer factories | Small to medium material processing plants |

Manufacturers often start with a powder granulator for smaller projects before scaling up to an NPK dry granulation production line for industrial operations.

Conclusion

The combination of NPK dry granulation equipment and powder granulator machines represents the future of efficient, sustainable fertilizer and mineral production. These technologies eliminate the need for costly drying systems, reduce environmental impact, and produce high-quality granules that meet the demands of modern agriculture and industry.

Whether you are looking to establish a large-scale NPK fertilizer plant or seeking a compact solution to convert fine powders into valuable products, these machines provide the ideal balance of performance, durability, and cost-efficiency. By investing in advanced granulation systems from trusted manufacturers like Yushunxin Machinery, businesses can enhance productivity, support sustainable practices, and achieve long-term profitability in the competitive fertilizer market.

Deepak Sharma

Namaste! I’m Deepak Sharma, the creative mind behind SocialFunda, your go-to hub for Facebook bios, captivating captions, Instagram bios, and a treasure trove of Hindi Shayari. As a digital enthusiast, I am passionate about curating content that adds a touch of flair to your online presence.